To call linear drains a ‘recent trend’ would be a misnomer. The product has been used in Europe and Australia for decades, yet it continues to generate sustained interest within design and build circles.

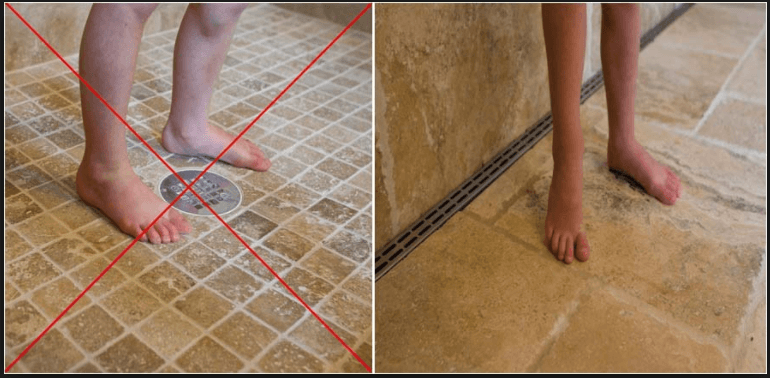

Also known as trench or channel drains, linear drains differ from other drainage alternatives by lying flush with its adjoining surfaces. In residential projects, this eliminates the need for shower curbs and means the drain may be installed away from the middle or standing area of a shower, offering a range of practical and aesthetic benefits.

For example, linear drains only require a single fall (or slope) in the floor, making them easier to install than a traditional ‘dished’ shower floor.

“Centre wastes require the floor to slope to the drain from all directions, like a shallow dish,” Stormtech’s managing director Troy Creighton explained. “A traditional centre waste is best in the middle of the floor as this is the shortest distance for any water to travel. The positioning of a linear drain is more versatile – it can be installed across the door, against the back wall, under a vanity, on one side of a shower or bathroom.”

This one-directional slope (towards the drain) not only makes for faster installation but builders also typically need less build-up on the floor and have more options on how to arrange the plumbing and waterproofing.

Linear drains are also favoured because they allow for large format stone or tiles (600 x 600, 600 x 300, 900 x 900) to be used without requiring cuts to create the correct falls. Compare this to traditional centre wastes, which are suited to smaller tiles since the ‘dish’ formed to guide water flow would require large tiles to be cut diagonally to avoid steps or lipping of the tiles.

An ‘add-on’ advantage of having a single fall that drains well in simple directions, is the floor cleaning process said Misho Vasiljevich, principal architect at Hobart practice Misho + Associates. Vasiljevich has specified linear drains both in residential bathrooms (using the Veitch shower channel, sold by Reece), and in commercial projects such as the Hobart Airport Terminal Redevelopment’s new toilets (Stormtech), forecourt expansion and airside drainage (Aco Drains).

The same benefits apply to the use of linear drains in commercial or public projects. A 2014 study by quantity surveyor Rider Levett Bucknall, which compared the cost and effectiveness of three drainage methods at a carpark at the Homebush Aquatic Centre in New South Wales, found that a modular grated trench drain system surpassed grated pit and pipe systems and cast in-situ trench drains in terms of hydraulic performance, and installation simplicity, and maintenance.

The same study also noted that the modular trench drain, the ACO Drain, was the more affordable option – 13 per cent cheaper than cast in-situ trench drains. However, some architects believe the higher costs associated with linear drains remain an inhibiting factor against their specification, particularly in residential projects.

“Practically and aesthetically, linear drains, in my opinion, have more upsides than downsides, but budget is the main driver until the plumbing trades become used to using them,” Vasiljevich said. “Like anything new, Australian trades [charge] high installation costs without looking at what it helps through all the trades.”

“On a recent project, the Quantity Surveyor placed a high cost on the supply and installation even though I had a quote. The client took the QS’ figures and linear drains were pulled from the project.”

Nevertheless, Vasiljevich and other architects we interviewed said they favoured linear drains over point drains.

“I definitely prefer linear drains and have used them on two recently completed projects,” architect Sophie Solomon said in an email interview. “We used large format floor tiles so the linear drain was the only option. For both projects, the linear drain was infilled with a matching cut tile so the floor looks quite seamless. They provide a superior finish and practical design solution in a wet area.”

“I would recommend point over linear drains when you have a low budget and cannot afford linear,” said Vasiljevich, “but I believe in the next 10 years linear drains will become standard.”

LINEAR DRAIN INSTALLATION CHECKLIST

- Sufficient drainage: Incorrectly sized sub-sill can lead to significant moisture damage in walls and floors.

- Durability: Seek materials that are purpose-built to withstand the harsh Australian elements, and resist shrinkage and expansion. Coastal homes will benefit from threshold products manufactured with 316 marine grade, corrosion-resistant stainless steel that can handle high water flows, harsh chemicals and suspended chloroids.

- Safety: Reduce chances of injury by fitting a linear drain that blends in seamlessly with the floor surface.

- Standards: Threshold drainage must meet design requirements for access and mobility (AS1428.1-2009), and thresholds at doorways, in particular, must have a continuous path of travel and have a maximum rise of 35mm, maximum length of 280mm, maximum gradient of 1:8 and be located within 20mm of the door leaf which it serves. They must also meet requirements in AS3500.2 Sanitary plumbing and drainage.

SUPPLIERS

Stormtech offers an extensive range of linear drains suitable for bathroom applications. The majority come as a uPVC channel and 316 marine grade stainless steel grate, however, tile insert and anodised colour range options are also available.

Stripgrate offer four linear drain models, three of which come in a narrow 38mm width and with either tile or steel profile inserts. The fourth on offer is called Tilegap (pictured) and is a 48mm channel with a centre positioned linear blade. Because of its design and tile overlap, the Tilegap appears to be much smaller than its drainage capability.

Stainless Steel Drainage & Civil Pty Ltd

Stainless Steel Drainage & Civil Pty Ltd

SSDC’s Quick Turnaround Drain is the only all Australian made version on the market. It will be delivered to site within three business days which also includes custom placement of spigot outlet. It comes in 304 grade stainless steel and in either 100mm or 75mm wide varieties. SSDC’s Bollinger Series (pictured) can also accommodate a tile insert.

Aco’s Quartz range of shower channels are available in six standard lengths (700, 800, 900, 1000, 1200 and 1400mm), with the option of a centre or end outlet (63mm from end). They are available in a choice of eight grating designs that can be replaced for a new look. Seven of those grating designs also come in a matching pointdrain profile and all come with an option for integrated water-activated LED lights.

Aquabocci claims to be the world’s most versatile drainage systems. Its PVC channel system can be measured and cut to length, hole sawed for custom-placed spigot holes and configured into corners. Its Blade series inserts (pictured) are also height adjustable to match any tile or stone thickness.

Veitch provide shower channels in Original or Lowline range. The Lowline comes in a depth of 20mm while the Original is 35mm. Both come in standard lengths of 800, 900, 1200 and 1500mm but can be custom built to lengths of up to 2400mm. Veitch also allows outlets to be custom positioned. Both are available in three grate patterns and in either a satin or chrome finish 304 grade stainless steel.

Originally published http://www.architectureanddesign.com.au/features/product-in-focus/ by Geraldine Chua